Don’t pay up to 40% more for the non-value parts added to your “custom” axle.

Large corporations typically do not design their axles to your vehicle needs. Instead, they force you to design your vehicle to their axles.

Their idea of “customization” is to take their off-the-shelf” standard axles and add non-value parts that presumably “adapt” the axle to your needs. Yet all this design practice does is add up to 30 to 40% to your costs. That is NOT how Schafer Driveline engineers design your driveline. They truly customize your axle based on your specifications. In many cases, your Schafer design will be simpler, more functional and often less-costly than you thought possible.

Small enough to listen to your driveline needs. Capable of meeting them.

In your off-highway markets, there are no "off-the-shelf" solutions if you want to build a niche. That’s why Schafer Driveline starts by listening to you, then performing all of the calculations for gear strength, load capacity and speed requirements. With feature options like gear ratios, differential lock, high/low/neutral/reverse shifting, wheel-to-wheel width, wheel bolt pattern, custom bracketry and ground speed governor, Schafer Driveline can create a custom powertrain. You will never again design a vehicle around an existing axle.

Here are how Driveline’s capabilities will help you stand out in your markets.

Design Engineering

- 40 years of expertise in designing complete and complex powertrain solutions

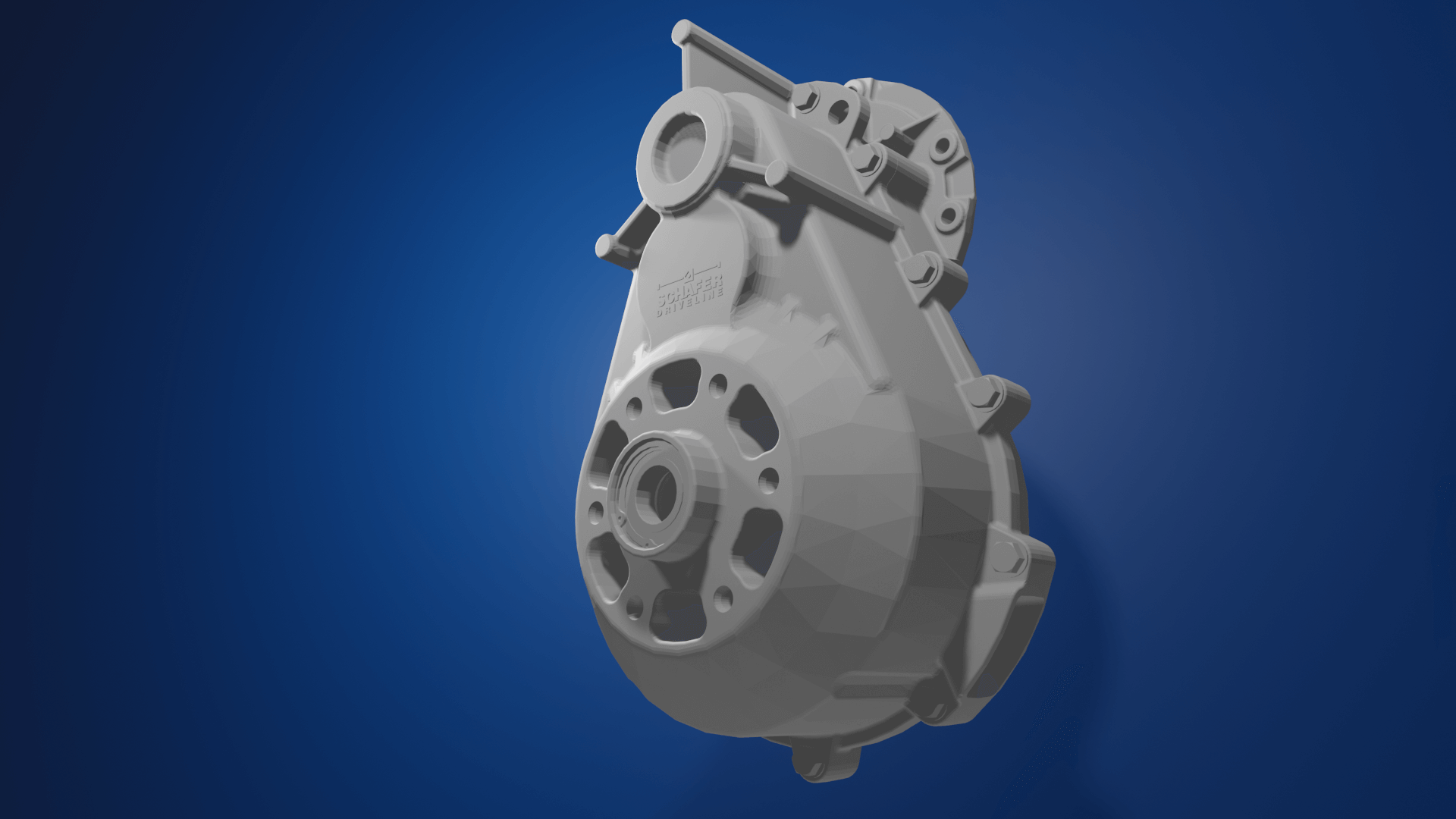

- Innovations for light- to heavy-duty electric-driven axles, light-duty gas-driven axles, gearboxes and brake systems

- Electrification specialists. Schafer Driveline starts with the center section of the standard axle model that best suits your vehicle specifications. Then we customize the axle ends, brakes, brackets, planetary and spur gearboxes, etc. to give you the driveline performance and reliability that helps your vehicles surpass the competition.

Volume Production

- High-volume assembly lines: 100,000+ units per year

- Low-volume assembly lines: 20,000 units per year

- Low-volume assembly cells: up to 4,000 units per year

- 0.5" to 36" inside diameter

Assembly

- Robotic and manual processes to ensure precision and quality

- Robust Poka-Yoke mistake-proofing systems in all assembly processes. This eliminates the human errors that cause defects in safety-critical products such as axles, brakes and gearboxes.

- Sophisticated end-of-the-line noise, spin, shift and air leak testing

A leader in on-time delivery

Missed delivery dates are one of the biggest frustrations in your business. If the drivelines, axles, gearboxes or brakes aren’t on your dock when you need them, you deal with costly production downtime. That’s why Schafer Driveline sets the bar high for on-time delivery in our industry. And if you face unanticipated production needs, call us. We are small enough to be agile, yet have the capacity to respond quickly to keep your lines running.